Simpler, more compact, and faster

The rotary system, which enables pouch forming, filling and sealing in the horizontal direction, achieves ultra-high-speed pouch packaging at 200 to 800 pouches per minute.

Also, the longer filling time allows for less bite into the sealing area and longer sealing time, resulting in stable sealing strength.

By combining a stacking device, the machine can be connected to a cartoning machine, horizontal pillow machine, banding machine, bag feed seal pouch packaging machine and other machines.

Application examples

Granular dashi stock, powdered soups, seasonings, ingredients, granulated sugar, instant coffee, powdered cream, tea packs (tea, dashi), health foods, powdered soft drinks, drip coffee, powdered and granular pharmaceuticals, desiccants, oxygen absorbers, food additives, bath salts, capsules, tablets, pills, etc.

Features & benefits

- Achieves industry-leading throughput of 200 to 1,000 pouches per minute

- Variations for chute mounting to respond to diverse industries

- Long heat treatment time for reliable sealing and long filling time for a wide variety of materials

- As a packaging plant solution, it can be linked with peripheral devices.

- A wide variety of options for the downstream processes available

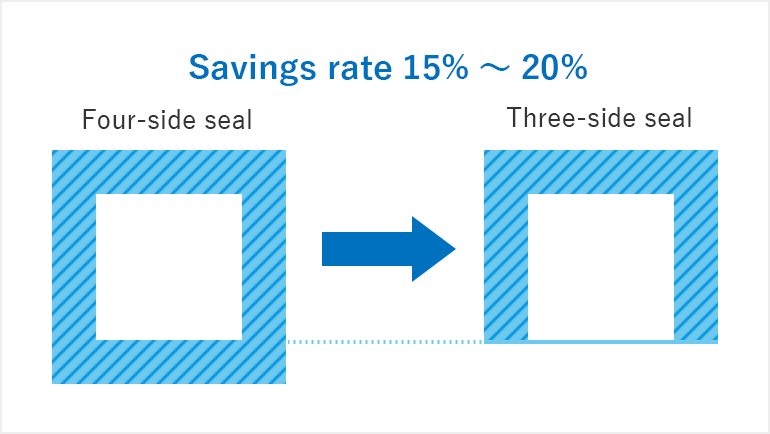

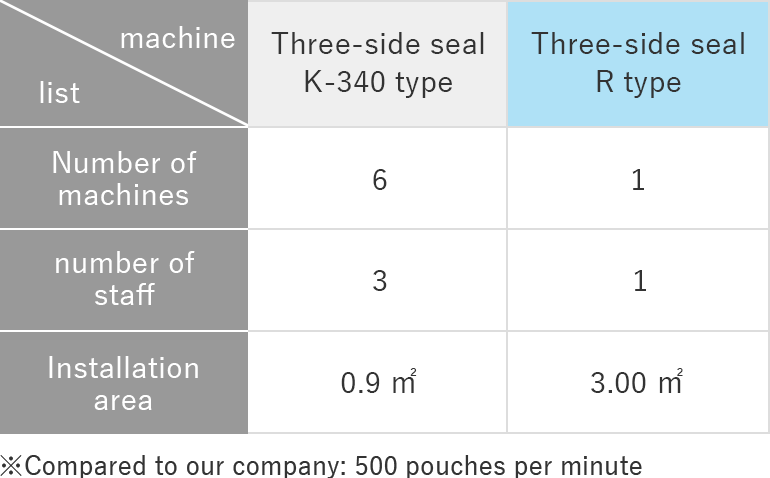

Cost reduction

Packaging material

Labor costs, etc.

| Series | R-35G R-35S |

R-36G R-36S |

R-51G R-51S |

R-52G R-52S |

|---|---|---|---|---|

| Print registration control | None | Included | None | Included |

| Packaging volume*1 | 0.5cc to 20cc | 0.5cc to 50cc | ||

| Packaging capacity*1 | 200 to 400 pouches per minute (Maximum film speed: 28 m per minute) |

200 to 800 pouches per minute (Maximum film speed: 42 m per minute) |

||

| Finished bag dimensions*1 | Length: 40 to 85 mm (Specified inside dimensions) Width: 30 to 90 mm (by replacing the film guide) |

Length: 40 to 125 mm (Specified inside dimensions) Width: 30 to 110 mm (by replacing the film guide) |

||

| Machine dimensions | Approx. 2,200 (W) × 710 (D) × 1,950 (H) mm | Approx. 2,500 (W) × 830 (D) × 1,980 (H) mm | ||

| Machine mass | Approx. 1,500kg | Approx. 2,000kg | ||

| Power consumption | Approx. 6 to 8kw | Approx. 6 to 10kw | ||

| Air consumption*2 | Approx. 0.5MPa・100L/min(ANR) | |||

| Power supply | 200 V, three-phase, 50/60 Hz | |||

| Standard accessory devices |

Automatic film coupling device

Film end detection device Hopper level detection device Seam tape detection device Chute part tapping device Heater disconnection detection device

Preheat bar open detection device

Automatic opening/closing device for preheating bar Rotary cutting device (G type only) Empty bag detection device Ejection device Overload detection device Safety cover with stop function |

|||

| Optional devices |

Bite detection device

Horizontal seal section gap detection device Seal pressure detection device Vertical seal temperature regulator (representative detection) Contact detection device for partitions in the turntable Intermediate chute device Dust collector Static eliminator Film reel air shaft Film tensioner Film ventilation hole processing device (needle hole roll type) Temporary four-side seal device Fine adjustment-type turntable Filling chute attachment/detachment device Printing device Printing inspection device Seal part engraving device Nitrogen gas filling device Automatic controller for cutting positions Multiple perforation cutting device I-notch cutting device

Special shape cutting device

Multi-filling device Collective rotary disk device Bucket conveyor device Sub-rotary disk device Feeder Super scale Auger filling device Tablet and pill counting device Belt conveyor Counting and separating device Counting and sorting device Stacking device Weight checker Weighing deviation feedback control Centralized lubrication device Touch panel Stainless steel cover Support for validation Special overseas specifications (UL/CE compliant) |

|||

- * Machines other than the above specifications can also be manufactured.

- * Type G is gear-driven and type S is servo motor-driven.

- * Type C, which does not have a cutting device and is gear-driven, is also available.

- *1 Figures vary depending on the filled item, packaging material and bag dimensions.

- *2 Air consumption figures are without optional devices.