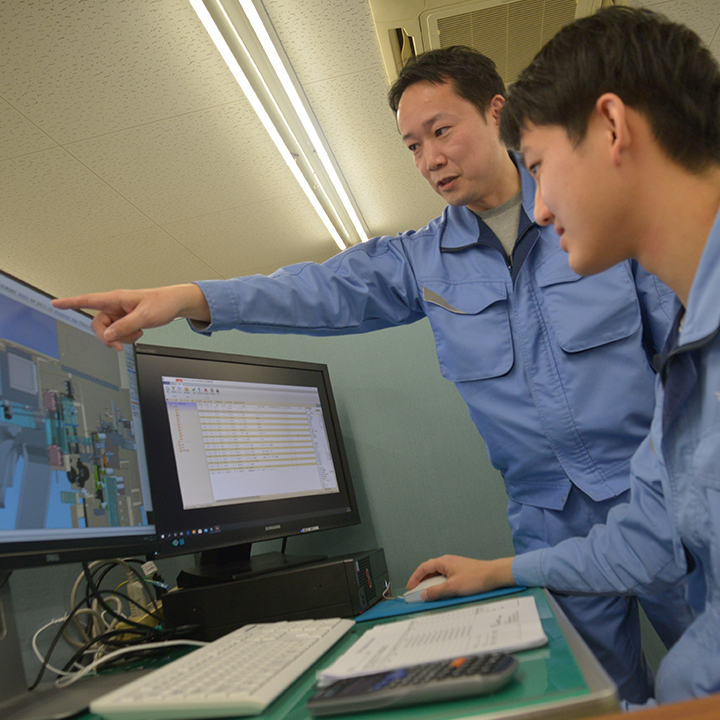

Comprehensive Line Proposal

We offer comprehensive packaging plant solutions from the view of the entire manufacturing process.

The role of Topack’s products is to improve productivity of customers’ lines and increase profitability.

To that end, it is necessary not only to provide automatic pouch packaging machines but also to comprehensively design the entire packaging process.

Topack has the know-how to design and propose a series of processes from those prior to packaging, such as material control, weighing and discharge, to those after filling and packaging, such as stacking, banding, inspection and stamping.

Packaging Plant Solution Process Chart

Example of packaging plant solution

—Responding to various upstream and downstream processes—

Upstream processes

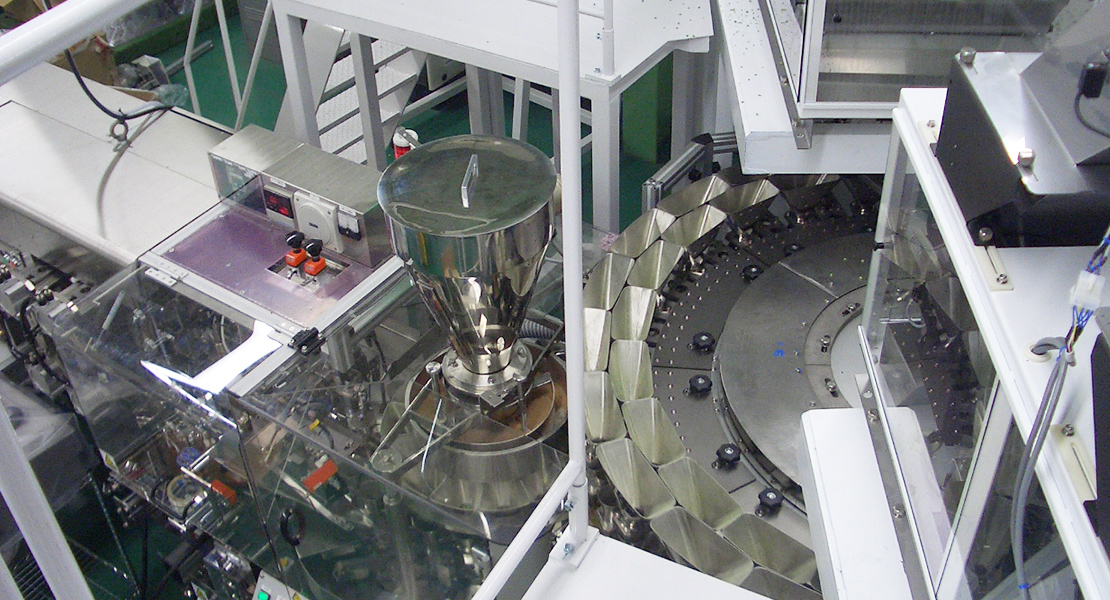

Super scale connection

Filled items that are difficult to accurately measure with a weighing mass (e.g., ingredients in dried soups) can be discharged while being accurately measured. With a speed of 300 pouches/min and a measuring accuracy of 0.1 g, optimum quality control is achieved at a reasonable cost.

Pneumatic transfer feeder

For continuous pouch filling and packaging, automation of raw material discharging is important. We can provide not only common screw-based feeders but also pneumatic transfer feeders that are less vulnerable to the inclusion of foreign matter. Automatic discharging can be achieved by linking with a sensor signal in the hopper. This increases workability and feeding efficiency at production sites.

Downstream processes

Single package transfer machine with a weight checker

Quality control requirements are becoming more precise and exacting every year. The single package transfer machine transfers separate pouches one by one, which are weighed with the weight checker on the way, and performs steps of row alignment, alternating stacking, etc. After the row alignment step, it can be connected to a wide range of downstream processes, sophisticating quality control and increasing productivity.

Stacking device for rotary-system automatic pouch packaging machines

We recommend the use of a stacking device that has been proven over the years with a rotary-system automatic pouch packaging machine. It automatically stacks packaged pouches at high speed. It is capable of stacking that is less likely to cause collapse by, for example, alternately inverting separate three-side seal pouches and stacking them and by transferring packages to the conveyor without free fall using the elevation system. This device has been highly evaluated by customers.

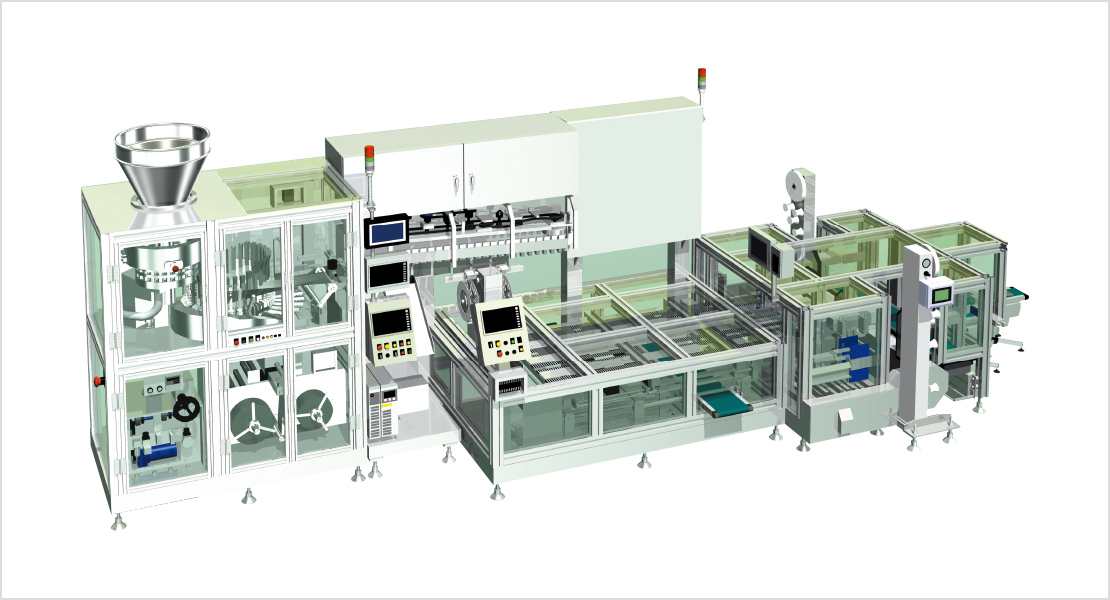

Example of packaging plant line

Pharmaceutical packaging line

A line designed to enable quantification for management data acquisition and to simplify cleaning supports high-efficiency production.

* We have a computerized system validation (CSV) system in place.

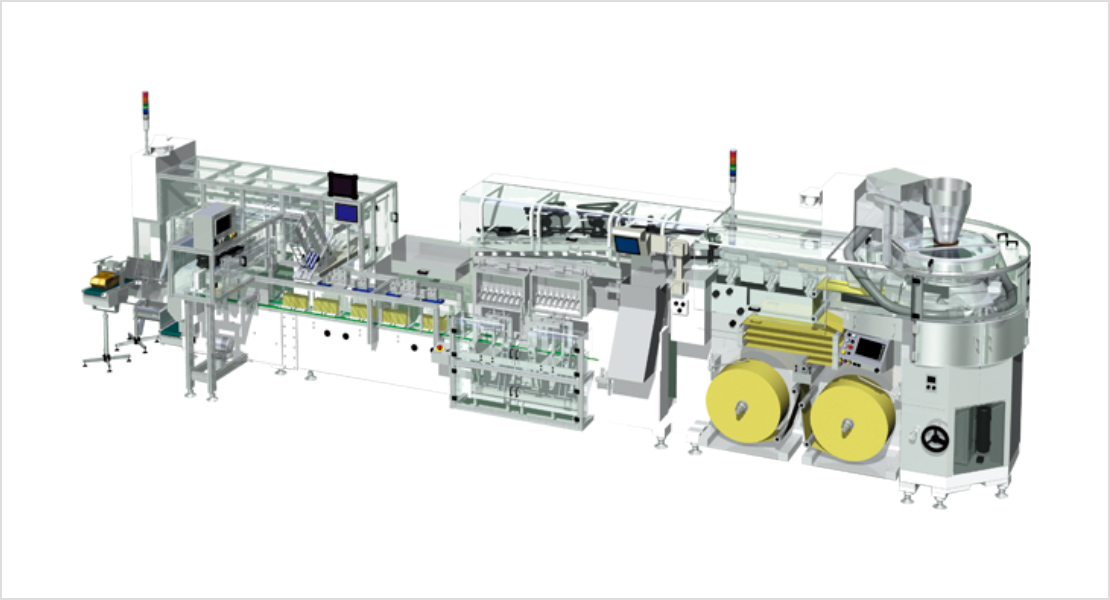

Ultra-high-speed packaging line

Packaging up to 1,000 pouches/minute is possible. We propose a comprehensive line system until gusset bag packaging by connecting a stacking device as a downstream process.