Quality Control

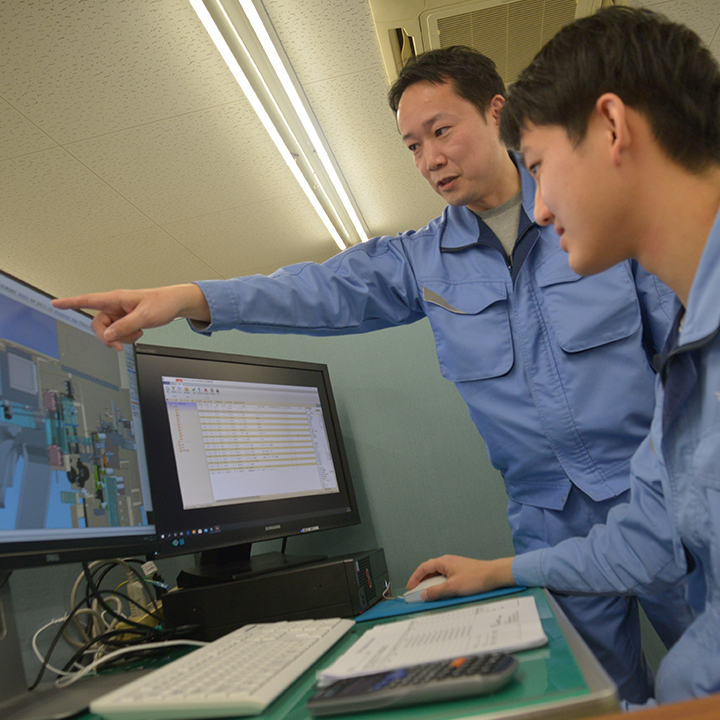

We have established a quality control system that thoroughly pursues reliability and safety.

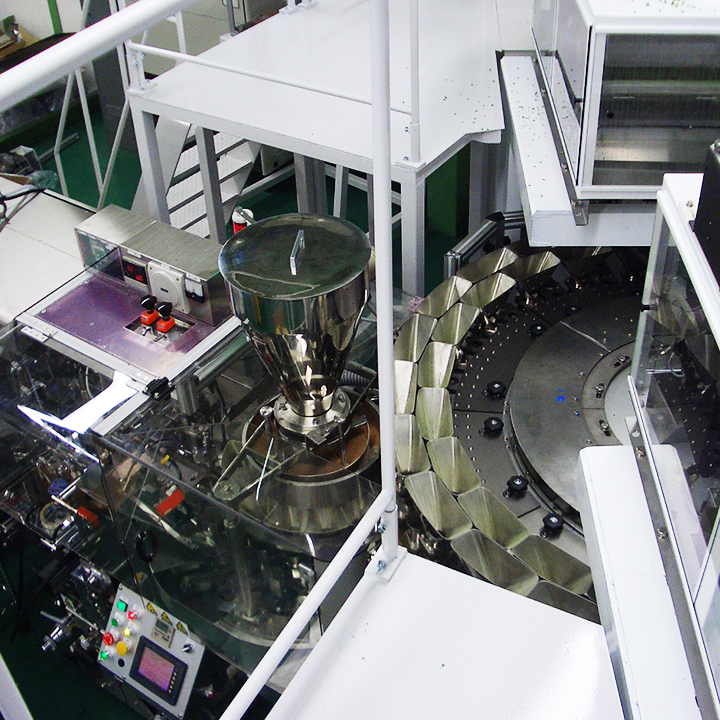

Most of Topack’s packaging machines are custom-made to ensure that every customer is satisfied with the machines.

Therefore, we have established a system to complete the assembly and adjustment of machines while sharing information with the customer on problems that occur on a daily basis.

We have established a strict quality control system in which just prior to delivery of the packaging machine, quality judgment inspections, including visual, specifications and functional inspections, are conducted by all concerned parties.

Improving quality of individual parts through cooperation with partner companies

A Topack packaging machine may consist of more than 10,000 parts. More than 90% of them are supplied by partner companies, and it is essential to maintain the quality of each and every part to improve the quality of the packaging machine. Therefore, we have created guidelines to ensure uniform inspection standards among partner companies and provide guidance on a daily basis. We have a system to supply high-quality parts by sharing information on problems that occur at our partner companies and measures to improve quality.

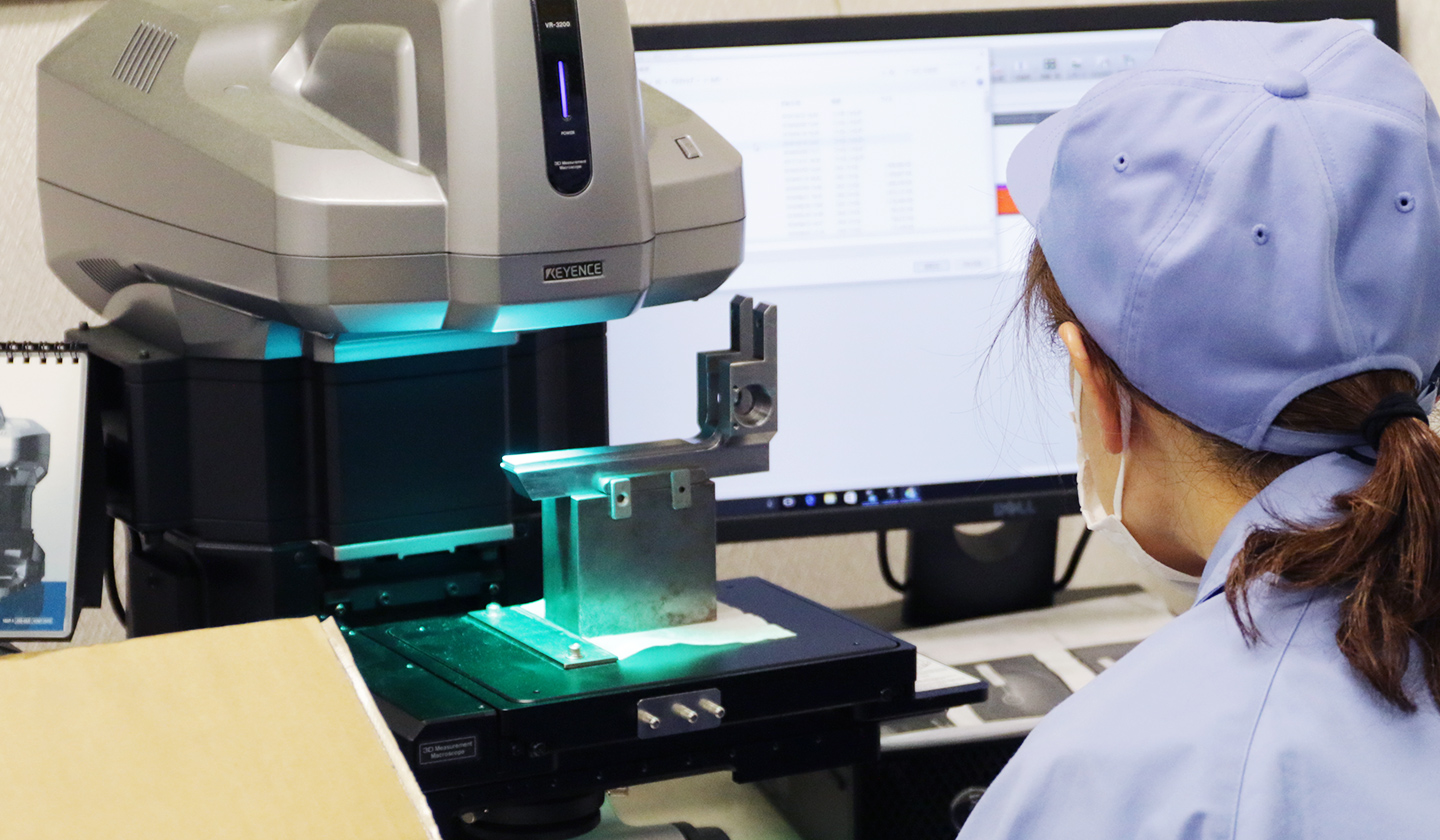

Quality inspection of the smallest parts determines the quality of each packaging machine.

The smallest parts supplied to Topack after inspection by our partner companies are also strictly inspected one by one in the Quality Control Department under the same standards. This double inspection ensures the quality of the smallest parts. We conduct thorough quality inspections under the motto “The quality of each packaging machine is determined by the quality inspection of the smallest parts.