Automatic pouch packaging machines

World-recognized automatic form, fill and seal technology

Solving problems with highly complete proposals

Topack’s mission is to solve problems associated with automatic pouch packaging to serve our customers’ business.

Towards this goal, we have been striving for more than half a century to refine our own technology to create automatic systems for pouch forming, filling and sealing as well as to develop world recognized ultra-high-speed automatic pouch packaging machines.

We always offer solutions to problems related to automatic pouch packaging by providing sophisticated automatic pouch packaging machines as well as technologies for the entire production line, including upstream and downstream processes.

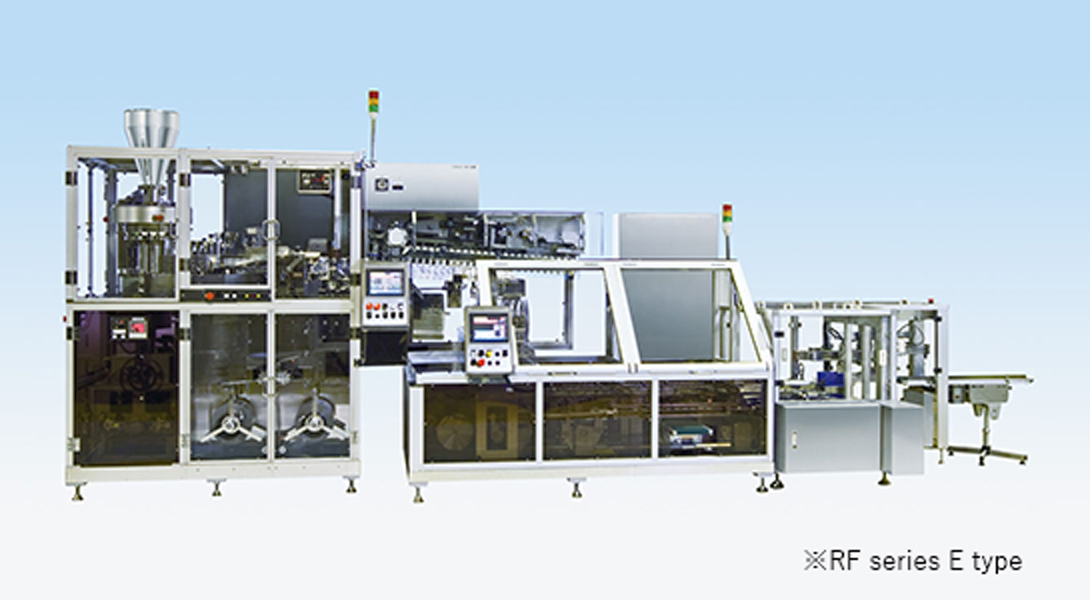

Complete product lineup to meet a wide range of needs

Topack offers a wide range of products to meet the diverse needs of our customers in terms of production output and scale, required speed, and productivity.

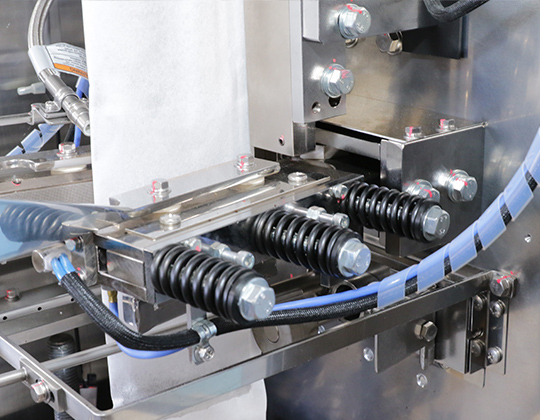

Various adjustment functions to improve sealing quality

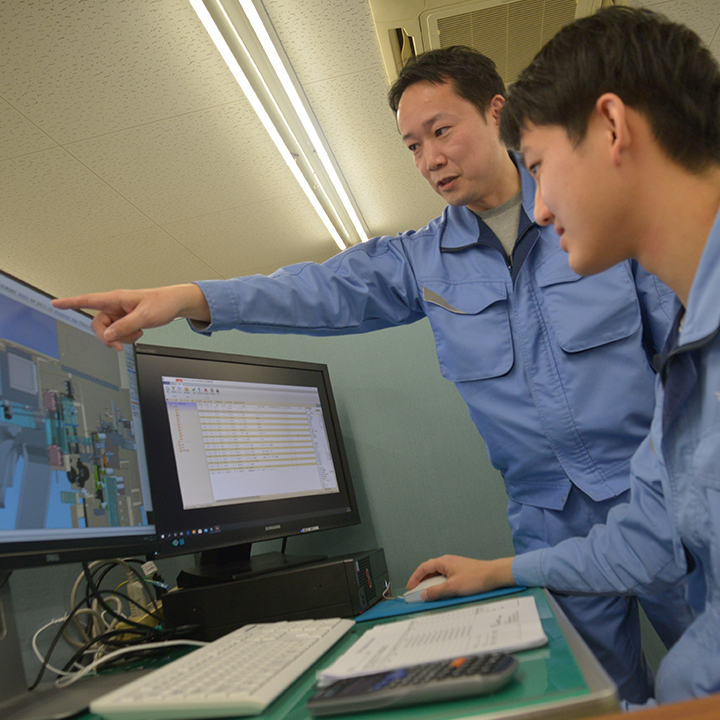

Topack’s automatic pouch packaging solutions focus on solving our customers’ most difficult challenges.

Many customers are concerned especially about packaging film edge breaks, seal wrinkles, package waves and other quality-related problems. We design and control packaging machines so that we can isolate the cause of even the smallest problem and provide a reliable solution, thereby appropriately solving problems to improve productivity and quality.

Independent control of vertical and horizontal sealing

Vertical-type automatic pouch packaging machines can independently adjust vertical and horizontal sealing. They resolve a wide variety of inconveniences.

Filling angle control

The filling angle can be adjusted to improve filling speed and ensure reliable filling.

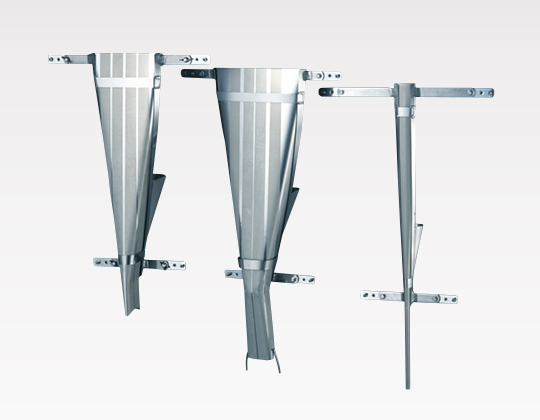

Diverse chutes

A wide variety of chutes are available according to powder characteristics. We propose the most suitable chute.

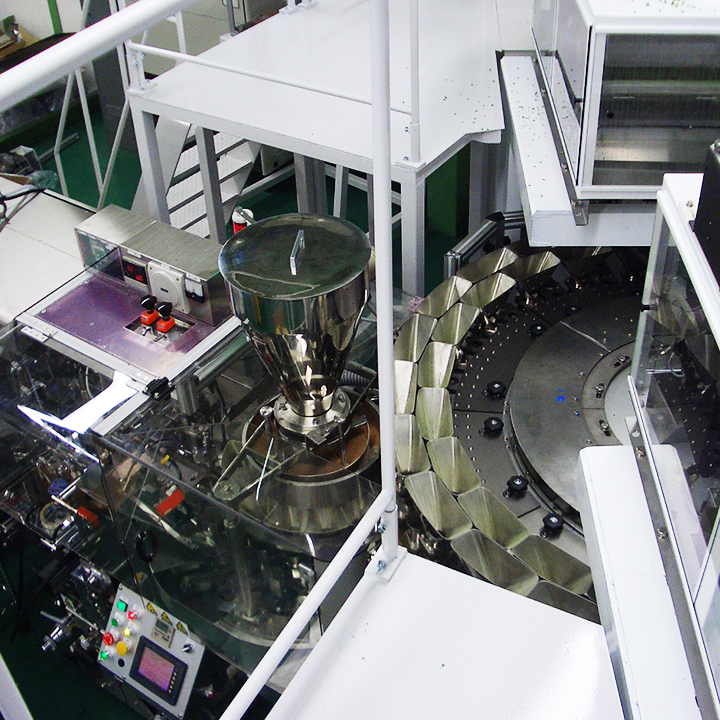

Hopper adjustment and control

We also propose the optimal hopper based on our experience involving the angle, shape, material, etc.

Providing comprehensive technologies, including those for upstream and downstream processes

To improve our customers’ profit margin and production efficiency, we can respond flexibly to their needs for human resources saving by mechanizing and automating not only the automatic pouch packaging but also processes before and after that process. We propose measures to meet customer needs, such as weighing at the time of raw material discharging and connection to processes after the automatic pouch packaging, including packaged items stacking, banding and inspection, stamping, bag feeding, and boxing.

Auger filler, computer scale, measuring cup, weigher, stacking device, banding device, box making machine, weight sorter, printer, CCD camera inspection machine, metal detector, x-ray inspection machine

Proposing innovative automatic pouch packaging

We can handle the packaging of products that have never been packaged before and the development of new production processes. Our long history of working together with customers to solve their problems has resulted in the provision of our own original machines to a wide variety of customers across industries. We can propose new packaging lines by applying packaging technologies that are well-established in other industries in terms of high efficiency, safety and stability to your industry as well.

Owning many proprietary technologies, including basic patents

Topack’s technologies have been always solution-oriented. As a result, many patented technologies have been created from the products that we have developed to date. We use a variety of original technologies to solve our customers’ problems involving automatic pouch packaging.

Patents obtained

- In Japan

- 157 patents, 4 utility models, 15 design registrations

- Overseas

- 7 patents, 4 design registrations

Examples of patents and proprietary technologies held by Topack

- Basic foundation of rotary-system automatic pouch packaging machines

- Elevation system stacking device that is less likely to cause collapse

- Quantification of sealing pressure

- Vertical and horizontal independent sealing mechanism