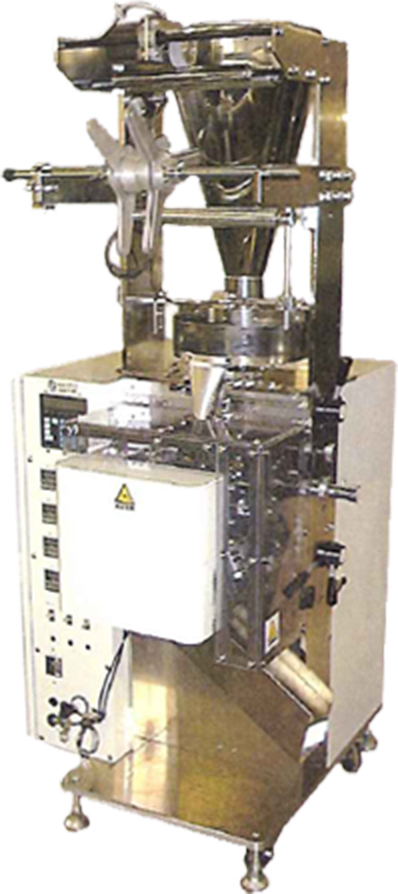

Ideal for delicately forming pouches for pharmaceuticals, etc. with a highly complete seal finish

Features & benefits

- Equipped with a panel with a product memory function, allowing easy resizing

- The standard servo motor drive allows for easy pouch length changes.

- Compact design and space-saving installation

Application examples

Powdered soups,seasonings, ingredients, granulated sugar, instant coffee, Powdered cream, health foods, powdered soft drinks, tablets・pills and powdered and granular pharmaceuticals, desiccants oxygen scavenger, food additives, bath salts, etc.

| Series | K-440 | K-444 | M-440 | M-444 |

|---|---|---|---|---|

| Pouch type | Three-side seal pouch | Three-side seal pouch Four-side seal pouch |

Three-side seal pouch | Three-side seal pouch Four-side seal pouch |

| Packaging volume*1 | 0.5 to 30cc | 30 to 150cc | ||

| Packaging capacity*1 | Maximum 40 to 80 pouches per minute | |||

| Finished bag dimensions*1 | Width: 30 to 100 mm Length: 60 to 110 mm |

Width: 30 to 120 mm Length: 120 to 240 mm |

||

| Machine dimensions | 695(W)×730(D)×1,800(H)mm | 695(W)×730(D)×1,900(H)mm | ||

| Machine mass | Approx. 400kg | Approx. 450kg | ||

| Power consumption | Approx. 2kw | |||

| Air consumption*2 | Approx. 0.5Mpa・70L/min(ANR) | |||

| Power supply | 200 V, three-phase, 50/60 Hz | |||

| Standard accessory devices |

Print registration mark controller

Heater disconnection detector Film tension controller Film end detector

Film forming guide knocking device

Rotary cutting device Safety cover with interlock Body cladding |

|||

| Optional devices |

Joint tape detector

Horizontal seal contamination detector Empty pouch detector Seal pressure detector Intermediate chute with shutter Dust collector Dust collection timing valve device Static electricity remover Film edge winding device Defect pouch rejector Data code printer Data code print inspection device Nitrogen gas flushing device I-notch cutting device Multiple cutting device with perforator Zigzag cutting device Punch hole device Cut timing adjustment device

Hopper level detector

Telescopic type of turntable Multiple products filling device Multiple products assembling chute Bucket conveyor Belt conveyor Sub turntable Vibration feeder Petit scale Auger filler Tablet and pill counting device Counting and dividing device Counting and grouping device Weight checker HMI Validation support Special overseas specifications (UL/CE compliant) |

|||

- * Machines other than the above specifications can also be manufactured.

- *1 Figures vary depending on the filled item, packaging material and bag dimensions.

- *2 Air consumption figures are without optional devices.