A stick-type pouch packaging machine equipped with a servo motor appears.

Space-saving machine for overwrap-type and fin seal packaging, also enabling mass production

Features & benefits

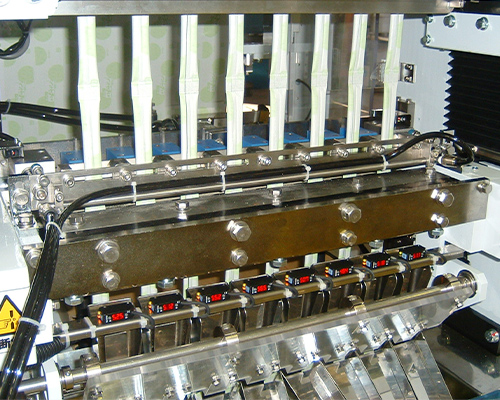

- Equipped with our original servo system

Servo motor control is used for film pitch feed to increase packaging capacity. The pouch length can be easily changed by setting numerical values.

Servo motor control is used to drive the weighing table, making it easy to make subtle timing adjustments by setting numerical values. - Easy operation with a product memory function

A touch panel is included that allows registration of 20 different products and makes it easy to change product information by simply entering the product number when changing products. - Easy line formation

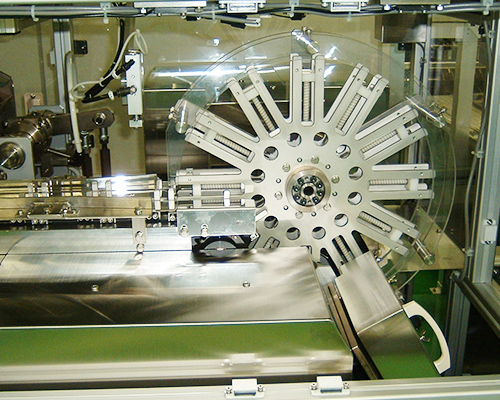

By combining a stacking device, the machine can be connected to a cartoning machine, horizontal pillow machine, bag feed seal pouch packaging machine and other machines. - Space saving by downsizing

Machine height has been reduced, further improving operability.

Application examples

Powdered soups,seasonings, ingredients, granulated sugar, coffee, Powdered cream, health foods, powdered soft drinks, tablets・pills and powdered and granular pharmaceuticals, desiccants, Oxygen scavenger, food additives, bath salts, etc.

Original equipment, functions and services of multi-row system automatic pouch packaging machine series

Comparison of characteristics between single-row and multi-row systems

| Single-row fill machine | Multi-row fill machine | |

|---|---|---|

| Number of machines | The number of machines can be adjusted according to production volume. Increased production in stages is also possible. |

The number of machines can be adjusted according to production volume. Increased production in stages is also possible. |

| Packaging material management | Material management for each single-row machine is required, which tends to be troublesome. | Feeding multiple rows from a single roll of film is possible, saving labor for packaging material management. |

| Series | SL | |||

|---|---|---|---|---|

| Print registration control | Included | |||

| Number of rows*1 | 2 to 14 | |||

| Packaging volume*2 | 0.5 to 50cc | |||

| Packaging capacity*2 | 20 to 70 pouches per minute/row | |||

| Finished bag dimensions*2 | Width: 11 to 60 mm (Specified inside dimensions) Length: 30 to 140 mm (Servo motor control) |

|||

| Machine dimensions | Approx. 1,250 to 1,600(W)×1,500(D)×2,200 to 2,600(H)mm | |||

| Machine mass | Approx. 1,500 to 2,000kg | |||

| Power consumption | Approx. 6 to 8kw | |||

| Air consumption*3 | Approx. 0.6Mpa・800L/min(ANR) | |||

| Power supply | 200 V, three-phase, 50/60 Hz | |||

| Standard accessory devices |

Print registration mark controller

Variable capacity weighing table Heater disconnection detector Film tension contraller Film end detector

Film forming guide knocking device

Overload detector Safety cover with interlock HMI Film edge slitter |

|||

| Optional devices |

Joint tape detector

Hopper level detector Horizontal seal contamination detector Empty pouch detector Seal pressure detector Intermediate chute with shutter Dust collector Dust collection timing valve device Static electricity remover Film reel air shaft Film edge winding device Defect pouch rejector Data code printer Data code print inspection device Nitrogen gas flushing device Multiple cutting device with perforator Zigzag cutting device Round corner cutting device

Punch hole device

I-notch cutting device Multiple products filling device Multiple products assembling chute Bucket conveyor Sub turntable Vibration feeder Petit scale Tablet and pill counting device Belt conveyor Counting and dividing device Stacking device Weight checker Product weight feedback system Body cladding Validation support Special overseas specifications (UL/CE compliant) |

|||

- * Machines other than the above specifications can also be manufactured.

- *1 The number of rows is limited by the pouch width.

- *2Figures vary depending on the filled item, packaging material and bag dimensions.

- *3Air consumption figures are without optional devices.