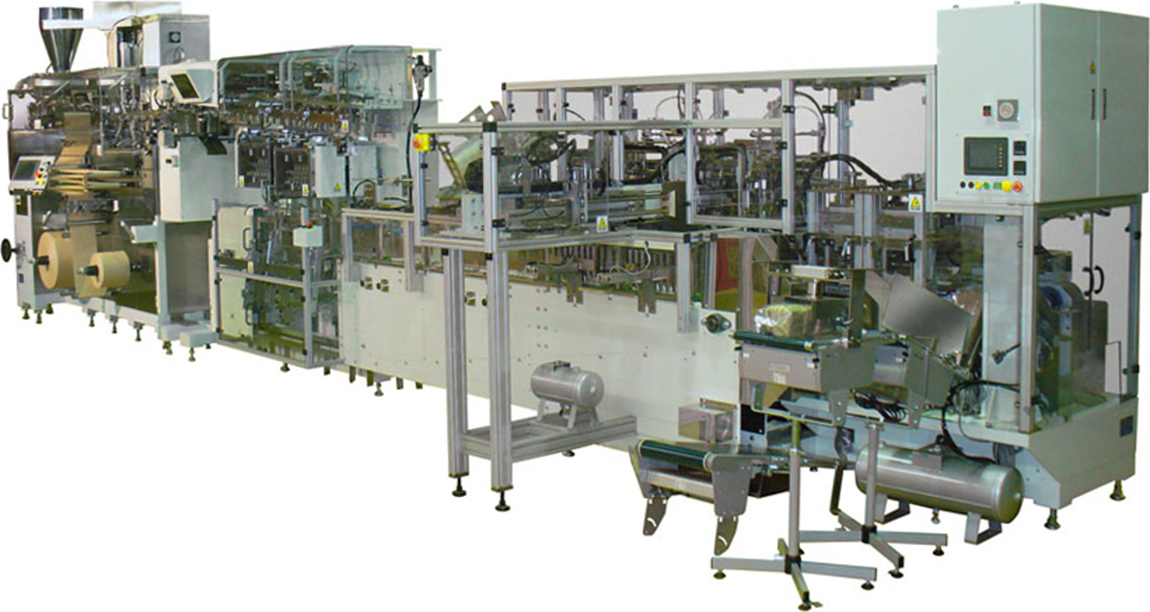

Compact bag feed seal pouch packaging with alignment system This unique and original method contributes greatly to cost reduction by reducing size and post-processing.

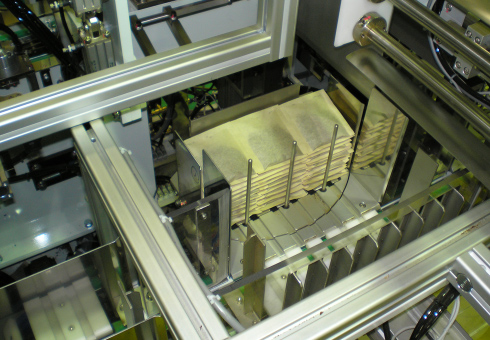

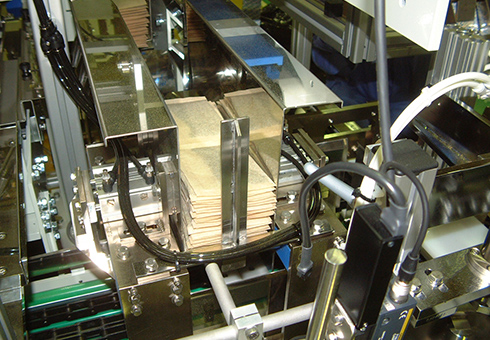

Our bag feeder adopts a unique alignment and horizontal insertion system. This eliminates wasteful packaging space (headspace), as is the case with drop-from-top systems, and enables compact, aligned packaging of bags. Compact packaging also contributes to cost reduction by reducing the size of product transport. With features, including the ability to insert paper mounts or trays, this machine series can efficiently increase productivity while maintaining the quality of the finished product with manual packaging. It is highly acclaimed as a hidden bestseller.

Features & benefits

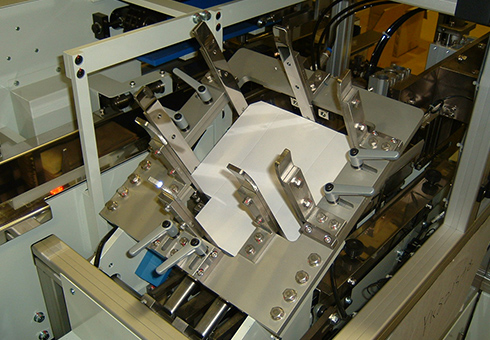

- Compact packaging is possible because the items to be packaged are conveyed horizontally and inserted into the outer pouches while being pressed.

- It can be used for both gusset bags and flat bags. (Parts replacement is required.)

- A printing device (IJP, ribbon type, laser) and a printing inspection device can be mounted.

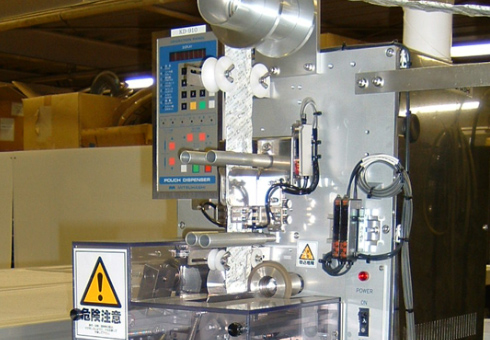

- Nitrogen gas filling is possible.

- Feeding deoxidizers and desiccants is possible.

- A bottom box is formed, and the item to be packaged is placed in the bottom box and then horizontally inserted into an outer pouch.

- Feeding paper mounts is also possible.

- The outer pouch magazine is equipped with an outer pouch level sensor.

- The outer pouch feeder with our proprietary structure achieves space saving and enables continuous feeding during operation.

- Products are discharged at desk height, facilitating inspection work.

Application examples

Tea bags, coffee bags, coffee sticks, Oxygen scavenger, furikake

Connectable to various stacking and banding processes

| Finished product | Required machine |

|---|---|

Gusset bag with a paper mount and an oxygen absorber |

|

|

|

|

|

|

|

Freely connectable to our pouch packaging machines (rotary system, multi-row system)

A system to increase production efficiency can be established by connecting to our high-speed packaging machines (rotary system and multiple row system).

Introduction track record

- Food products

- Tea packets, coffee, malted rice, okonomiyaki flour

| Series | BG |

|---|---|

| Packaging capacity*1 | 5 to 60 pouches per minute |

| Pre-made bag dimensions*1 | Length: 290 to 350 mm Width: 120 to160 mm Height: 45 to 100 mm |

| Machine dimensions | Approx. 2,000 to 2,700(W)× Approx. 1,000 to 1,500(D)× Approx. 1,700(H)mm |

| Machine mass | Approx. 2,000kg |

| Power consumption | Approx. 8kw |

| Air consumption*2 | Approx. 0.5MPa・500 to 800L/min(ANR) |

| Power supply | 200 V, three-phase, 50/60 Hz |

| Standard accessory devices | Heater disconnection detector Pre-made bag magazine empty detector Safety cover with interlock HMI |

| Optional devices | Data code printer Data code printer inspection device Pouch dispenser Paper tray supplying device Weight checker Belt conveyor |

- * Machines other than the above specifications can also be manufactured.

- *1 Figures vary depending on the filled item, packaging material and bag dimensions.

- *2 Air consumption figures are without optional devices.